Size Matters

Miura’s unique compact Modular Boiler design utilizes a low-volume pressure vessel offering output capacities comparable to much larger traditional, outdated boilers. The resulting smaller boiler footprint provides design flexibility, reduced construction costs and more options with existing spaces. A Miura boiler system is so flexible, you can have multiple boilers working on the same system in separate installations or install Miura boilers at the point-of-use in order to eliminate energy loss through line transmission.

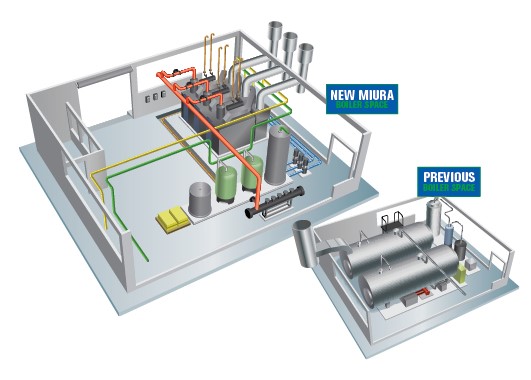

The compact footprint of Miura boilers offers great flexibility when designing a new or reconfiguring an existing boiler room. In addition to being half the size of a traditional boiler plant, Miura boilers eliminate tube pull-space and door-swing space requirements typical of conventional designs. This allows configuration of the boiler room for double the output of an existing boiler plant or reduction of its size by over fifty percent.

The compact footprint of Miura boilers offers great flexibility when designing a new or reconfiguring an existing boiler room. In addition to being half the size of a traditional boiler plant, Miura boilers eliminate tube pull-space and door-swing space requirements typical of conventional designs. This allows configuration of the boiler room for double the output of an existing boiler plant or reduction of its size by over fifty percent.

The Modular Difference

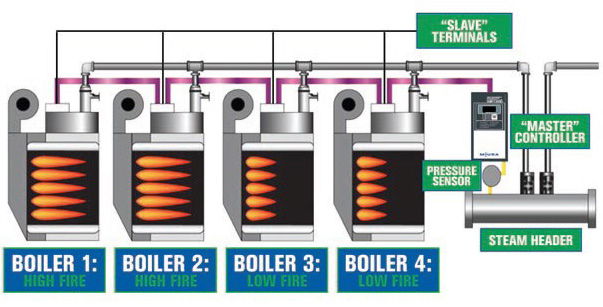

For larger loads, multiple Miura boilers are far superior to a single large conventional boiler.

With our innovative “MI” (Multiple Installation) system, you can build an on-demand steam plant customized to meet your specific demand requirements. The MI system provides the flexibility to build to current steam loads within very tight tolerances while allowing easier future expansion of system capacity. The multiple modular units also enhance a facility’s energy management capability by providing higher efficiency during part-load/standby conditions via the MI system’s ability to stage multiple units on or off in response to demand fluctuations. And because boilers cycle on and off independently, there’s no shutdown for routine maintenance. With a half-day inspection per boiler, you never lose steam and never experience plant shutdown.

With our innovative “MI” (Multiple Installation) system, you can build an on-demand steam plant customized to meet your specific demand requirements. The MI system provides the flexibility to build to current steam loads within very tight tolerances while allowing easier future expansion of system capacity. The multiple modular units also enhance a facility’s energy management capability by providing higher efficiency during part-load/standby conditions via the MI system’s ability to stage multiple units on or off in response to demand fluctuations. And because boilers cycle on and off independently, there’s no shutdown for routine maintenance. With a half-day inspection per boiler, you never lose steam and never experience plant shutdown.

- Automatically stage boilers to meet demand fluctuations

- Provide equivalent boiler capacity in less than half the space

- Save up to 20% in annual fuel costs

Scalable Solutions

By the nature of the modular approach, a Miura system is inherently much more scalable than a comparably sized traditional boiler room solution. Because of their compact size and compatibility, it’s easy to add or subtract boilers as needs increase or decrease.