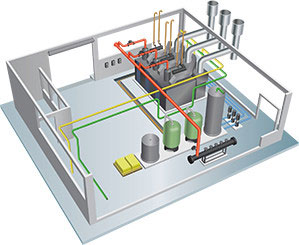

MIURA MANUFACTURES VIRTUALLY EVERY COMPONENT NEEDED

FOR A TURN-KEY BOILER ROOM SOLUTION.

FOR A TURN-KEY BOILER ROOM SOLUTION.

Miura is the only steam manufacturer that can partner with you for a comprehensive online maintenance system and total pressure vessel warranties against workmanship and water treatment issues. We are the leader among the steam boiler suppliers. Our complete systems are optimized to work together, to maximize efficiency and performance. That means you get the steam you need faster, and more economically that ever before.

A Turn-key boiler room includes:

A Turn-key boiler room includes:

- Modular Boiler Systems

- MW Water Softener

- BOILERMATE® Water Treatment

- Feedwater Tank

- Feedwater Pumps

- Brine Tank

- Steam Header

- Master Controller Communication Systems

- Chimney Stacks

- Installation Services

- Maintenance Systems

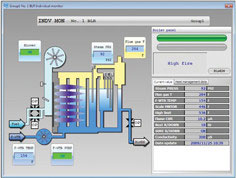

WITH THE PRESS OF A SINGLE BUTTON, MIURA BOILERS PRODUCE STEAM IN FIVE MINUTES OR LESS.

Would you buy a car that needs to idle all night long or warm up for 90 minutes before you can drive it? Of course not. So why put up with that for your boiler? There’s no-warm up necessary. In five minutes or less from start-up, you’ve got steam to run your processes, heat your facility or whatever you need it for, when you need it. Miura’s boilers feature fast starts that track precisely to drastic load swings. With our innovative “MI” (Multiple Installation) system, you can build an on-demand steam plant customized to meet your specific demand requirements. Our MI system provides the flexibility to build to current steam loads within very tight tolerances, and our more efficient boilers are synchronized to give you the steam you need and cycle on and off when you don’t need it.

Miura boilers meet lower NOx standards, reduce maintenance and monitoring needs, and reduce space requirements. And they do it with the most real-world, in-service efficiency possible, saving you up to 20% on fuel costs.

Miura boilers meet lower NOx standards, reduce maintenance and monitoring needs, and reduce space requirements. And they do it with the most real-world, in-service efficiency possible, saving you up to 20% on fuel costs.

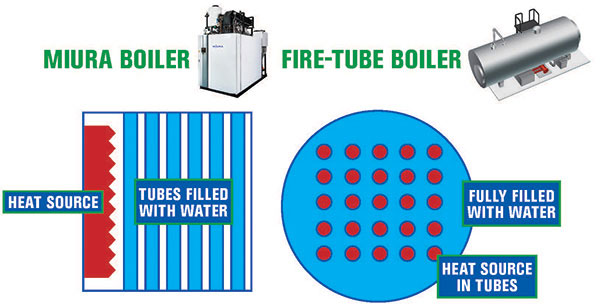

SMALLER IS BETTER

Miura’s unique, compact modular design utilizes a low-volume pressure vessel, offering output capacities comparable to much larger traditional, outdated boilers. The resulting smaller boiler footprint provides design flexibility, reduced construction costs and more options with existing spaces. Miura boilers eliminate tube pull-space and door-swing space requirements typical of conventional designs. This allows configuration of the boiler room for double the output of an existing boiler plant or reduction of its size by over fifty percent. And a Miura boiler system is so flexible, you can have multiple boilers working on the same system in separate installations or install Miura boilers at the point-of-use in order to eliminate energy loss through line transmission.

Read more about modular boilers and why size matters.

Read more about modular boilers and why size matters.

MIURA SAVINGS SOLUTIONS

Miura’s low water volume design results in optimal heat transfer with fuel-to-steam efficiencies of 85% +/- at all load conditions, which in turn, can save hundreds of thousands of dollars per year.

Read more about Miura’s Saving Solutions

Read more about Miura’s Saving Solutions

WE MAKE MAINTENANCE EASY AND FAST

A well-maintained Miura boiler provides the highest efficiency throughout the life of the system and protects this important investment. It’s an essential part of keeping your Miura boiler running like the day you bought it. And with a 3-hour shutdown for routine inspections, you don’t have to lose a whole day or shut the whole plant down. Just shut down one modular boiler and keep the others up and running. From water analysis, to our MOM online support systems, to overall efficiency, our Miura boiler maintenance program ensures that you’ll save down time while saving energy costs. Plus, most parts are covered free, and emergency service is available should you need it.

Learn more about Miura Maintenance

Learn more about Miura Maintenance

A WARRANTY YOU CAN COUNT ON, AND THE ONLY MANUFACTURER WHO GUARANTEES IT

Miura is known around the world for our dedication to quality and our ongoing drive for excellence. Our products are supported by the best engineering technology in the industry and every Miura boiler is backed by a warranty you can count on. By choosing Miura’s maintenance & inspection program, you’ll be making a wise decision assuring worry-free boiler operation.

Our guarantee covers most parts and labor costs, as well as the industry’s only Pressure Vessel Guarantee (with the MMC/MMRC program only) against corrosion. By selecting our maintenance & inspection program, you enlist Miura’s expert stewardship over the long-term reliable and efficient operation of your boilers.

Download a printable version of our warranty

Our guarantee covers most parts and labor costs, as well as the industry’s only Pressure Vessel Guarantee (with the MMC/MMRC program only) against corrosion. By selecting our maintenance & inspection program, you enlist Miura’s expert stewardship over the long-term reliable and efficient operation of your boilers.

Download a printable version of our warranty

SAFETY SOLUTIONS

With more than 200,000 units in operation world-wide, Miura has never had a pressure vessel explosion. Ever. Miura boilers are intrinsically safer by design. With low water content combined with the unique boiler geometry, catastrophic vessel failure is practically impossible. Miura boilers also have numerous safeguards beyond primary vessel safety to ensure not only safe operations, but also high efficiency and reliable operation.

QUICK TO STEAM, QUICK TO OPERATION

Miura can have your boiler delivered in as little as 2 weeks if your model is in stock. Custom builds can ready in as little as 8 weeks. Our manufacturing plant is running and stocked, ready to deliver your next boiler solution. And with factory training available from a certified Miura engineer, you can be sure your system is up and running and worry-free from the first time you fire it.

TESTIMONIALS

"Our steam load varies from 5,000 PPH (Pounds Per Hour) to 50,000 PPH, so we were looking for a dependable and reliable boiler system that could give us the proper amount of steam for the low- and high-demand times. Our previous boilers could not run on low loads, and the efficiency would decrease drastically. The Miura boilers are very efficient and environmentally friendly, and require very little attention when operating, plus they take up a lot less room."

- Jack Avant, Engineering Manager, Gulistan Carpet

"We were running a pretty efficient operation, but with Miura technology, we estimated an additional 10 to 20% fuel saving, and that really got our attention."

– Paul Gackel, PE, Director of Facilities/Utilities, Spangler Candy

"Right now North Carolina is in a drought situation. I’m attending lots of meetings on what can be done about water conservation and Miura boilers, because they are so small and efficient, have really put us way ahead of everybody around town – and this industry – on water conservation."

– Shannon Clifton, Engineering Supervisor, Duke Raleigh Hospital

Back To Top- Jack Avant, Engineering Manager, Gulistan Carpet

"We were running a pretty efficient operation, but with Miura technology, we estimated an additional 10 to 20% fuel saving, and that really got our attention."

– Paul Gackel, PE, Director of Facilities/Utilities, Spangler Candy

"Right now North Carolina is in a drought situation. I’m attending lots of meetings on what can be done about water conservation and Miura boilers, because they are so small and efficient, have really put us way ahead of everybody around town – and this industry – on water conservation."

– Shannon Clifton, Engineering Supervisor, Duke Raleigh Hospital