Every time you go to the grocery store, you buy food that’s been processed and packaged with the help of an industrial steam boiler. Whether you realize it or not, steam and hot water produced by boilers play an integral role in the food we consume every day. It only seems appropriate to take a closer look at how boilers contribute to food processing.Contact Us

Every time you go to the grocery store, you buy food that’s been processed and packaged with the help of an industrial steam boiler. Whether you realize it or not, steam and hot water produced by boilers play an integral role in the food we consume every day. It only seems appropriate to take a closer look at how boilers contribute to food processing.Contact Us

When it comes to industrial boilers, as with anything else, efficiency is the name of the game. For judging the fuel efficiency of boilers, most rely on fuel-to-steam efficiency, which is the most popular measurement for boiler efficiency. However, fuel-to-steam efficiency doesn’t always tell the whole story. Another way to judge an industrial boiler system is to calculate its in-service efficiency.Contact Us

When it comes to industrial boilers, as with anything else, efficiency is the name of the game. For judging the fuel efficiency of boilers, most rely on fuel-to-steam efficiency, which is the most popular measurement for boiler efficiency. However, fuel-to-steam efficiency doesn’t always tell the whole story. Another way to judge an industrial boiler system is to calculate its in-service efficiency.Contact Us

At the heart of any chemical processing plant is a great boiler system. In many ways, boilers are the unsung hero of any chemical processing operation. They have a significant impact on the productivity and efficiency of chemical producers. Let’s take a closer look at some of the ways that boilers are utilized during chemical processing.Contact Us

At the heart of any chemical processing plant is a great boiler system. In many ways, boilers are the unsung hero of any chemical processing operation. They have a significant impact on the productivity and efficiency of chemical producers. Let’s take a closer look at some of the ways that boilers are utilized during chemical processing.Contact Us

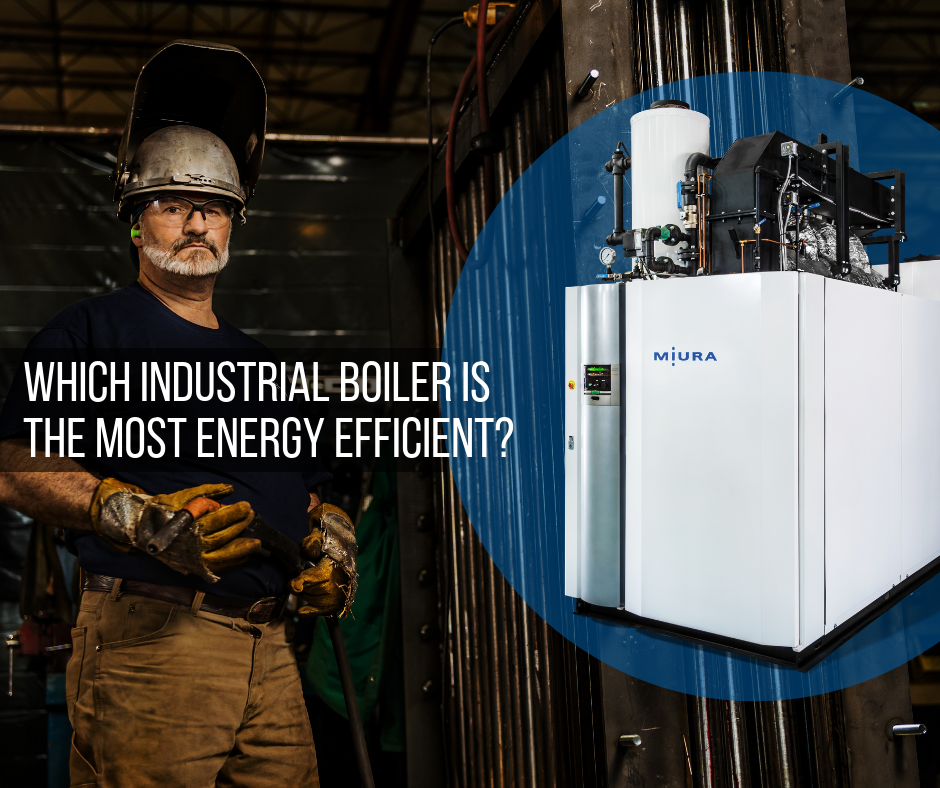

When it comes to industrial boilers, energy efficiency is the name of the game. Traditional fire tube boilers are notorious for consuming large amounts of fuel, but with the current cost of fuel, it’s now more important than ever to use boilers that can be as efficient as possible when it comes to fuel use and operating costs. While many boiler manufacturers have made an effort to adjust to the need for more fuel-efficient pressure vessels, the most energy efficient industrial boiler on the market is Miura’s LX series.Contact Us

When it comes to industrial boilers, energy efficiency is the name of the game. Traditional fire tube boilers are notorious for consuming large amounts of fuel, but with the current cost of fuel, it’s now more important than ever to use boilers that can be as efficient as possible when it comes to fuel use and operating costs. While many boiler manufacturers have made an effort to adjust to the need for more fuel-efficient pressure vessels, the most energy efficient industrial boiler on the market is Miura’s LX series.Contact Us

To keep a Miura boiler running for as long as possible at optimal levels, there are a number of maintenance chores that must be performed every now and then. One such piece of upkeep is called a bottom blow down. This is something that must be done intermittently in order to remove particles, sludge, and any other type of sediments that may have settled at the bottom of the boiler and started to accumulate in the piping.Contact Us