The first thing you should know about steam boilers is that no two boilers are created equal. From the outside, it may seem like all boilers are more or less the same. However, there are several different types of boilers with different qualities, different designs, and different purposes. Before you can have an idea of which boiler is right for your facility, you should become acquainted with the more common types of steam boilers.Contact Us

The first thing you should know about steam boilers is that no two boilers are created equal. From the outside, it may seem like all boilers are more or less the same. However, there are several different types of boilers with different qualities, different designs, and different purposes. Before you can have an idea of which boiler is right for your facility, you should become acquainted with the more common types of steam boilers.Contact Us

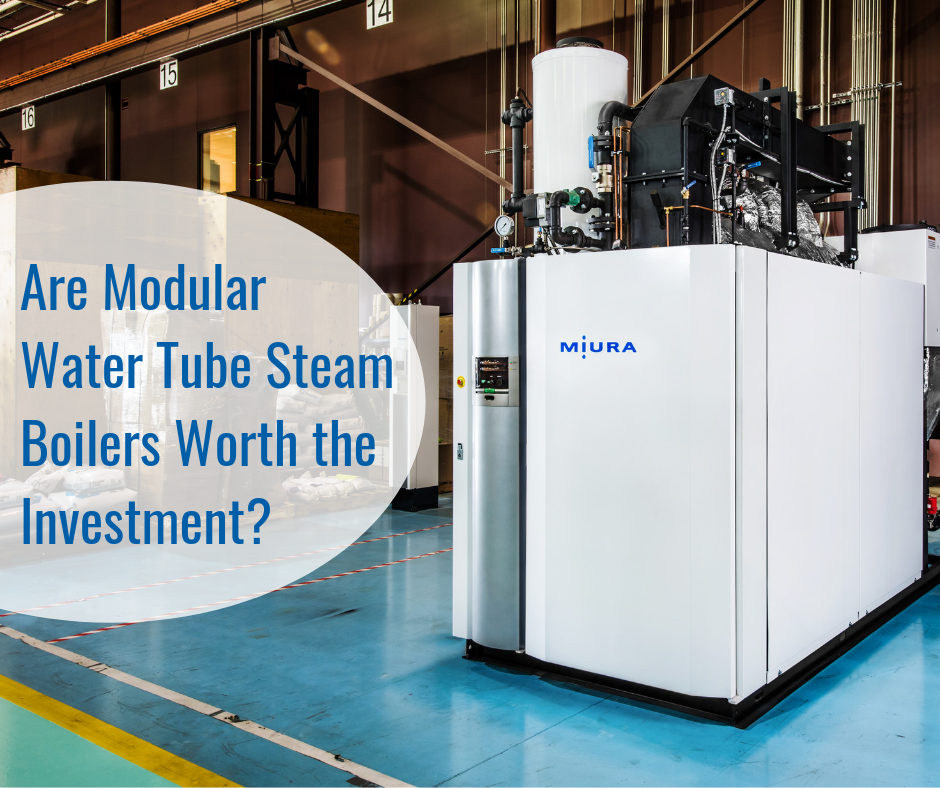

Modern advances in boiler technology are creating a shift from traditional fire tube boilers in favor of modular water tube boilers. Of course, to follow along with the trend, you have to commit to the cost and hassle of replacing your old boilers. If you’re wondering if making the switch to modular water tube boilers is worth it, let’s take a closer look at some of the benefits of these new, modern boilers.Contact Us

Modern advances in boiler technology are creating a shift from traditional fire tube boilers in favor of modular water tube boilers. Of course, to follow along with the trend, you have to commit to the cost and hassle of replacing your old boilers. If you’re wondering if making the switch to modular water tube boilers is worth it, let’s take a closer look at some of the benefits of these new, modern boilers.Contact Us

The first U.S. hospital to choose Miura Boilers steams ahead with the “on-demand steam leader,” as it upgrades facilities and takes advantage of the newest technology.Contact Us

The food service industry relies heavily on steam for many applications. Their need for steam varies sometimes by the hour, which is why steam on-demand is such a plus for them. Hot Cuisine America, a division of the Univeg Group of Companies in Belgium, is no exception. This New Jersey-based company creates high-quality prepared meals for a range of food services and retailers, and as such they rely on boilers for everything from building heat to sanitation to driving the machinery. According to Hot Cuisine’s chief engineer Henry Kao, Miura boilers have been a great fit for their needs.

Contact UsProducing in excess of 25,000 barrels of ale per year, Asheville, NC-based Highland Brewing Company is North Carolina’s largest brewery of fine craft beers. A key turning point in the company’s output, however, occurred when they decided to expand their production capacity—which required a new boiler. Their choice of the Miura gas-fired LX-100 boiler has proven to be pivotal in their goals; since installing it, Highland reports that they’ve been able to increase output by 20 percent while actually reducing their energy costs by $1200/month.

Contact Us